Pioneering zero carbon pig iron plant in the USA

The HIsmelt Green Pig Iron Project will be one of the first green pig iron plants in the US, with a defined path to “Net Zero” carbon emissions. This project is expected to produce 1.3M tpa of pig iron in the Ohio Valley, using low-cost, locally sourced raw materials to produce the lowest cost pig iron in North America.

HIsmelt Technology

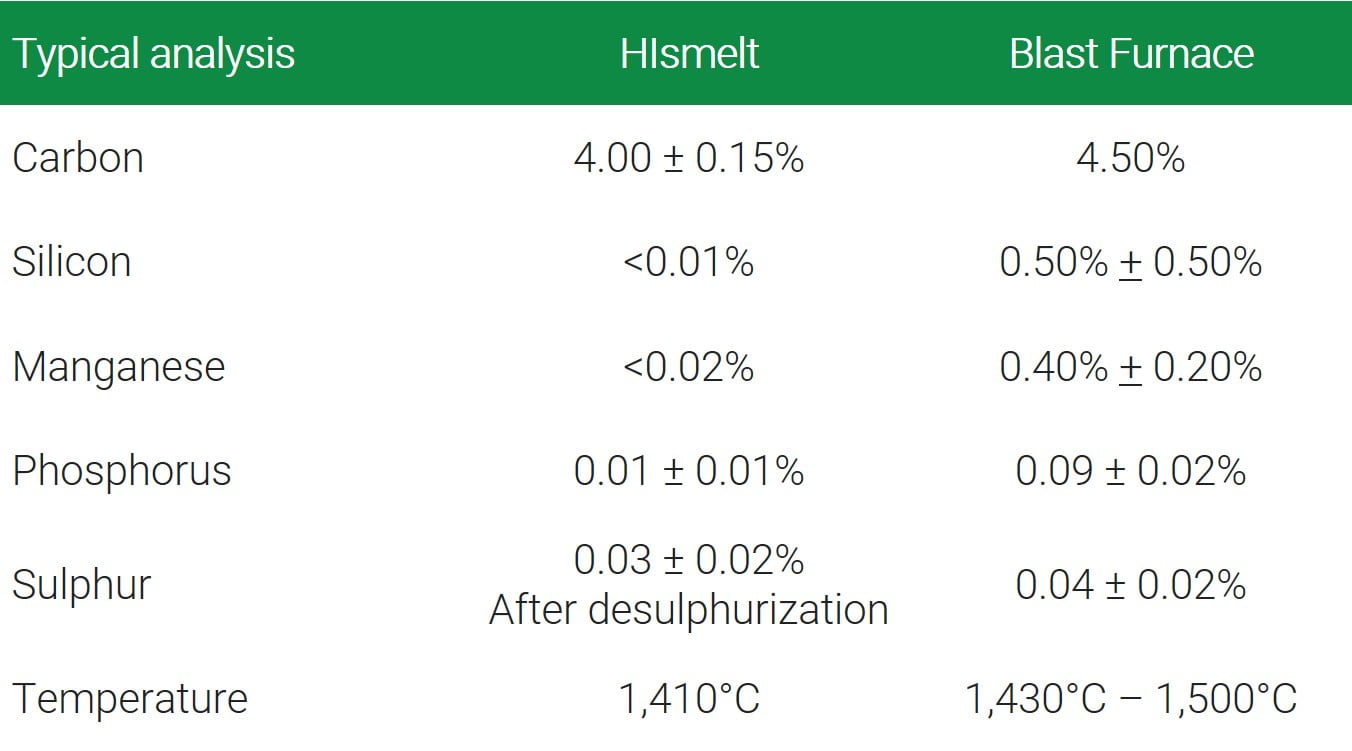

The Plant will use the HIsmelt iron-making technology, that has undergone 40-years of intensive development by the world’s leading mining and steel companies, with more than $1.5bn of investment to-date. HIsmelt Technology is the only proven, commercialised and environmentally acceptable alternative to the blast furnace globally.

Highly attractive economics

This project has a highly competitive target cash cost due to the unique flexibility of the HIsmelt process, which will allow the Plant to use locally sourced low-cost ferrous “wastes”, such as C-fines (ultra-fine slag fines that cannot be recycled elsewhere), millscale, steel works slags, dusts, sludges, as well as low-grade iron. The elimination of coke ovens, pellet plant and blast furnace (or pellet plant, DRI plant and melter) means low capital is required for this project.

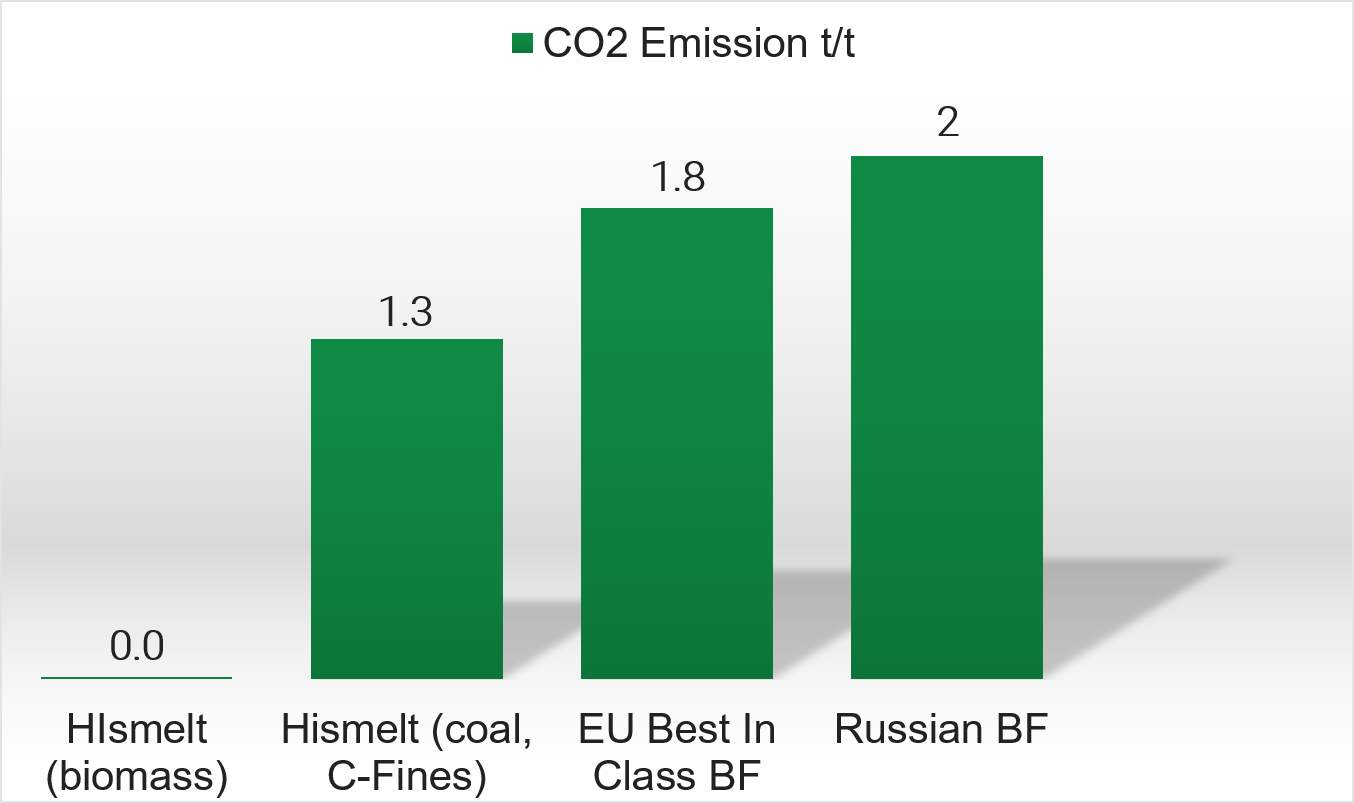

Significant “green credentials”

The Plant will emit “Net Zero” emissions via the use of locally sourced biomass char. Remediation and clean-up of legacy steel wastes, which cannot be recycled or removed profitably by any other operation. The plant generates excess power that can be used to generate hydrogen.